| Sign In | Join Free | My entremaqueros.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My entremaqueros.com |

|

Brand Name : HDB

Model Number : Boiler Manifold Header

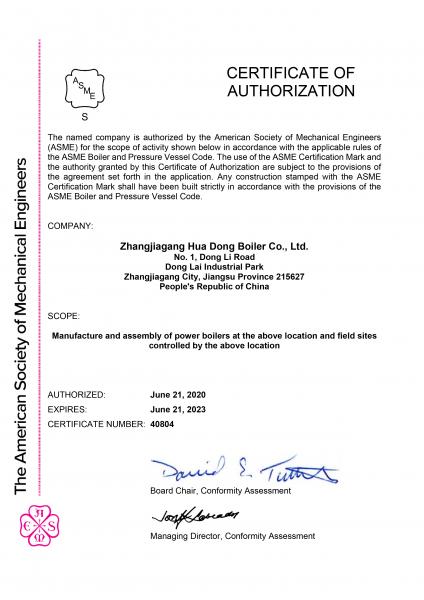

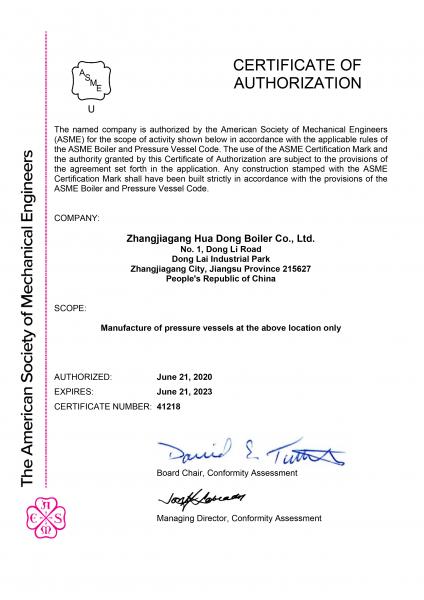

Certification : ISO9001 , SGS , TUV , ASME , EN

Place of Origin : Jiangsu , China

MOQ : 1 Set

Payment Terms : L/C, T/T

Condition : New

Working Temperature : 445 Degree

Type : Ultra Super Critical

Material : 15CrMoG / 12Cr1MoVG

OEM : Yes

Color : Customized

Specification : Customized

Packing : Iron Frame Package

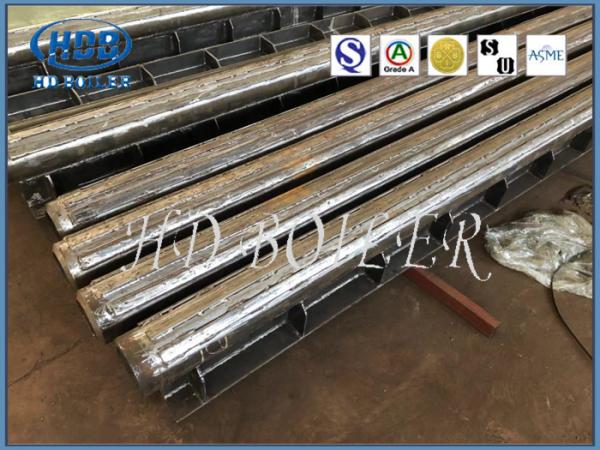

| 1 | Headers form an important part of all types of boilers. |

| 2 | Steam from the generating tubes is collected in headers which are therefore always under pressure. |

| 3 | This pressure may vary from 300 psi to 2000 psi. Since headers are always under pressure, the utmost care is taken by us while fabricating them. |

| 4 | Depending on the generating capacity of the boiler the header sizes fabricated by us vary from 100 mm to 600 mm NB. The stubs of various sizes are very carefully welded to the main body of the header to provide the desired openings from the header. |

The mainly function of manifold headers is to collect working material or distribute working materials to other pipes.That is collect,mix,distribute working material,ensure uniform distribution and heating.

Product Details

1.The necking hinders of the Company are made by hot press and retracting of seamless steel pipes at special hinder necking machine.

2.In this way, the hinders will have thicker walls and cleaner surface. The necking cover will form membrane stress rather than bending stress with desired stress performance under the effect of inner pressure.

Product Functions

The collecting box is the pipe fitting for boiler working medium mixing and ensuring uniform heating of working medium. Industrial boiler furnace wall is usually composed of rows and rows of tubes (water wall) together, but boiler huge volume, complicated structure, cannot guarantee that all the working medium in the pipe of heat absorption capacity is the same, different parts of heat absorption differs a lot, install header can let each pipe working medium inside converge here, the redistribution to the next level in the tube, so that we can reduce the thermal deviation, make the working medium heat, cooling flow, boiler, the boiler thermal efficiency are optimized to improve; In addition, the size, quantity and arrangement of pipes in the upper, middle and lower parts of the boiler are different, and the collecting box is responsible for connecting each section to ensure the smooth flow of working quality.

Product Features

Headers form an important part of all types of boilers. Steam from the generating tubes is collected in headers which are therefore always under pressure. This pressure may vary from 300 psi to 2000 psi. Since headers are always under pressure, the utmost care is taken by us while fabricating them. Depending on the generating capacity of the boiler the header sizes fabricated by us vary from 100 mm to 600 mm NB. The stubs of various sizes are very carefully welded to the main body of the header to provide the desired openings from the headers

Bevelling and weld preparation of stubs duly tack-welded to the main body of the header are first shown to Chief Inspector of Boilers for his approval and once again the stubs fully welded with main body are shown to Chief Inspector of Boilers under hydraulic pressure, varying from 1000 to 3000 psi as required by the specifications.

The headers are stamped by Chief Inspector of Boilers before they leave our manufacturing plant. We also weld skubolets and weldolets in place of stubs.

Classification

| Material | Carbon steel,Alloy steel,Stainless steel. |

| Length | According to costumes requirements. |

| Temperature Range | 300℃~1500℃ |

| Diameter(OD) | 76mm~914mm |

Certificate

Application

CFB distributing economizer header with high welding technique have water wall header, superheater header, economizer header and so on, it acts as collection, mixture, re-distributing working medium, as the structure, it can be classified as the end cover type( end enclosure) and necking down type.

|

|

High Efficiency Manifold Headers Heat Exchange Power Station Plant Boiler Parts Images |